The Art of Micro Mechanics

The world around us is shrinking. From the intricate mechanisms within our smartphones to the sophisticated medical devices that save lives, the demand for miniaturized components is constantly growing. This is the realm of micro mechanics, a specialized field that focuses on the design, fabrication, and assembly of extremely small parts, often measured in micrometers (millionths of a meter). Within this intricate world, the production of spring vents presents a unique set of challenges and opportunities, demanding precision, expertise, and innovative solutions.

Micro mechanics pushes the boundaries of traditional manufacturing techniques. It requires specialized equipment, highly skilled technicians, and a deep understanding of material properties at the microscale. Traditional machining methods often prove inadequate for such tiny components, necessitating the development of new approaches like micro-machining, lithography, and micro-electro-mechanical systems (MEMS) fabrication. These techniques allow for the creation of incredibly precise features and tolerances, essential for the proper functioning of micro-devices.

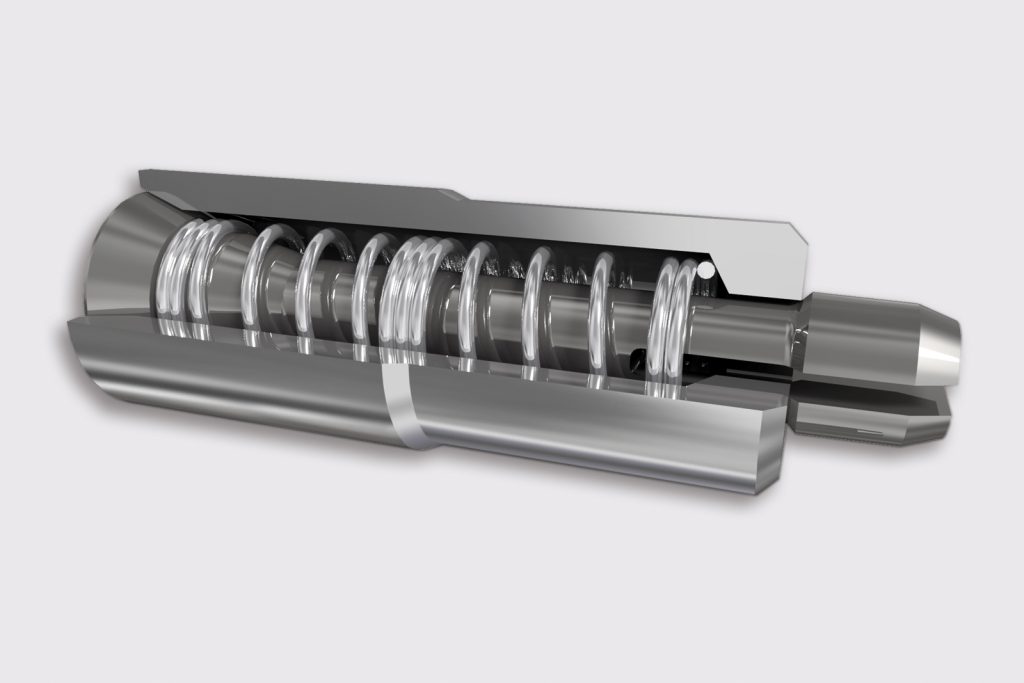

Spring vents, crucial components in a variety of micro-systems, exemplify the complexities of micro mechanical production. These tiny vents, often incorporating integrated springs, regulate airflow or pressure within miniature devices. Their applications range from microfluidic devices used in biomedical research to pressure sensors in automotive systems. The design of a spring vent must consider not only its size and function but also the specific requirements of the application, such as flow rate, pressure differential, and material compatibility.

The production of micro spring vents often begins with the selection of appropriate materials. Given their small size and demanding applications, these components require materials with specific properties, including high strength, elasticity, corrosion resistance, and biocompatibility (for medical applications). Common materials include specialized alloys, polymers, and even ceramics.

Once the material is chosen, the fabrication process begins. Micro-machining, using specialized tools and techniques, can be employed to create the basic shape of the vent and spring. Lithography, a technique borrowed from the semiconductor industry, allows for the creation of extremely fine features and patterns on a substrate, which can then be etched or processed to form the desired components. For even more complex designs, MEMS fabrication techniques, involving processes like thin-film deposition and etching, can be used to create highly integrated micro spring vents.

The assembly of micro spring vents presents another significant challenge. Due to their minuscule size, manual assembly is often impractical, if not impossible. Automated assembly techniques, such as robotic manipulation and pick-and-place systems, are becoming increasingly important. These systems require extreme precision and control to handle and position the tiny components without damage.

Do you need more information? Feel free to contact us

Form Form Form

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incidunt ut labore et dolore magna aliqua. Ut enim ad minim veniam, quis nostrum exercitationem ullamco laboriosam, nisi ut aliquid ex ea commodi consequatur. Duis aute irure reprehenderit in voluptate velit esse cillum dolore eu fugiat nulla pariatur. Excepteur sint obcaecat cupiditat non proident, sunt in culpa qui officia deserunt mollit anim id est laborum.