Pagani Works

The Production Process

Production is the lifeblood of any industry, the intricate dance of engineering, packaging, and specialized tooling that transforms raw materials into tangible products. It’s a process that spans a vast spectrum, from the initial design stages to the final packaged product ready for consumers. Whether it’s a complex electronic device or a simple cardboard box, the principles of efficient and effective production remain constant.

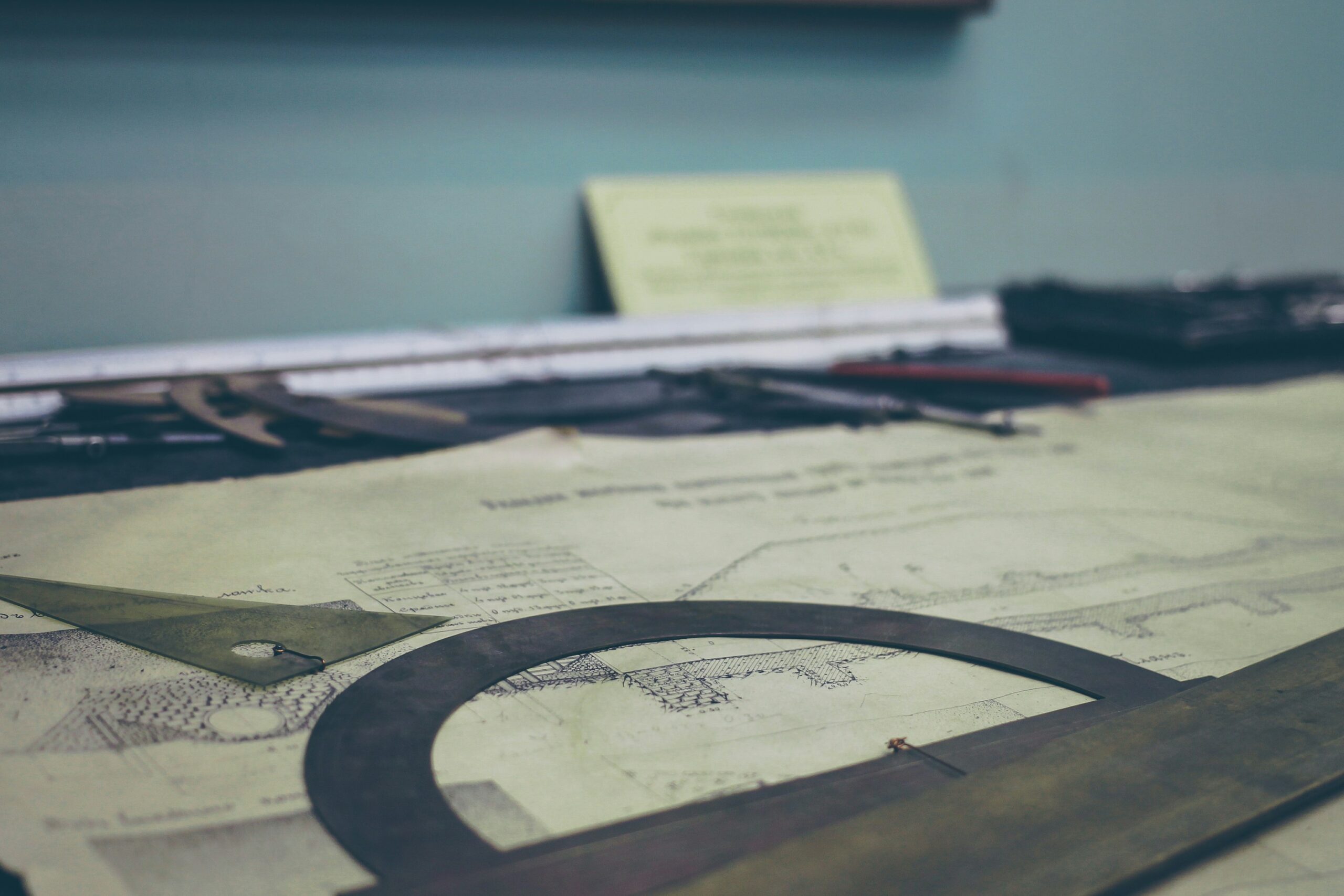

At its core, production involves a series of interconnected steps. It begins with engineering, where meticulous planning and design take place. Engineers utilize their expertise to create blueprints, schematics, and prototypes, defining the precise specifications of the product. This stage is crucial, laying the foundation for the entire production process and ensuring the final product meets the required standards of quality, functionality, and safety.

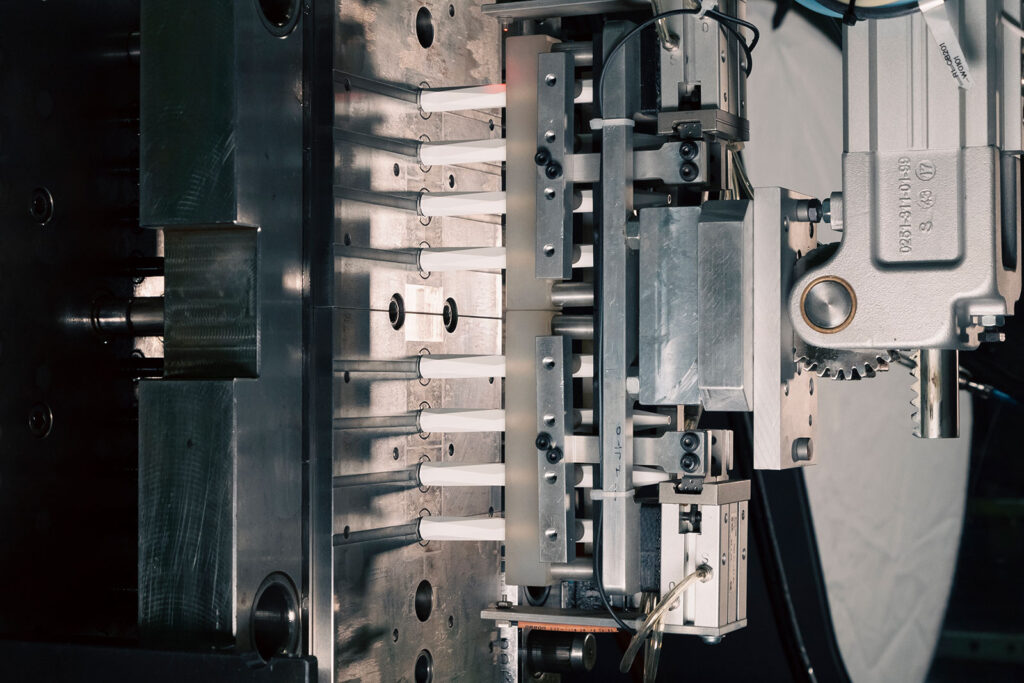

Once the design is finalized, the focus shifts to tooling and manufacturing. This often involves the creation of specialized tools, such as molds for plastic injection or dies for metal stamping. These molds and dies are precision-engineered to shape the raw materials into the desired forms, enabling mass production of identical parts. The accuracy and quality of these tools are paramount, directly impacting the quality and consistency of the final product.

The manufacturing process itself can vary significantly depending on the product and industry. It might involve processes like machining, assembly, or even 3D printing. Each step requires careful monitoring and quality control to ensure that the product adheres to the established specifications. This includes checking dimensions, material properties, and overall functionality.

Packaging plays a critical role in the final stages of production. Beyond simply containing the product, packaging serves multiple purposes. It protects the product during transportation and storage, preserves its quality, and provides essential information to the consumer. The design and materials used in packaging are carefully considered to optimize protection, cost-effectiveness, and aesthetic appeal. For products like food or pharmaceuticals, packaging also plays a crucial role in maintaining safety and extending shelf life.

Even the seemingly simple cardboard box represents a significant feat of production engineering. From the selection of raw materials to the cutting, folding, and gluing processes, every step is optimized for efficiency and cost-effectiveness. The design of the box itself is engineered to provide the necessary structural integrity while minimizing material usage.

In today’s competitive landscape, businesses are constantly striving to improve their production processes. This involves implementing lean manufacturing principles, automating tasks, and leveraging data analytics to identify areas for optimization. The goal is to minimize waste, reduce costs, and improve overall efficiency while maintaining or even enhancing product quality.

In conclusion, production is a complex and multifaceted process that involves a delicate interplay of engineering, manufacturing, packaging, and specialized tooling. From the initial design concept to the final packaged product, each step plays a vital role in delivering quality goods to consumers. Continuous improvement and innovation are essential for businesses to thrive in the dynamic world of production.

Do you need more information? Feel free to contact us

Form Form Form

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incidunt ut labore et dolore magna aliqua. Ut enim ad minim veniam, quis nostrum exercitationem ullamco laboriosam, nisi ut aliquid ex ea commodi consequatur. Duis aute irure reprehenderit in voluptate velit esse cillum dolore eu fugiat nulla pariatur. Excepteur sint obcaecat cupiditat non proident, sunt in culpa qui officia deserunt mollit anim id est laborum.

Pagani Works utilizza WordPress